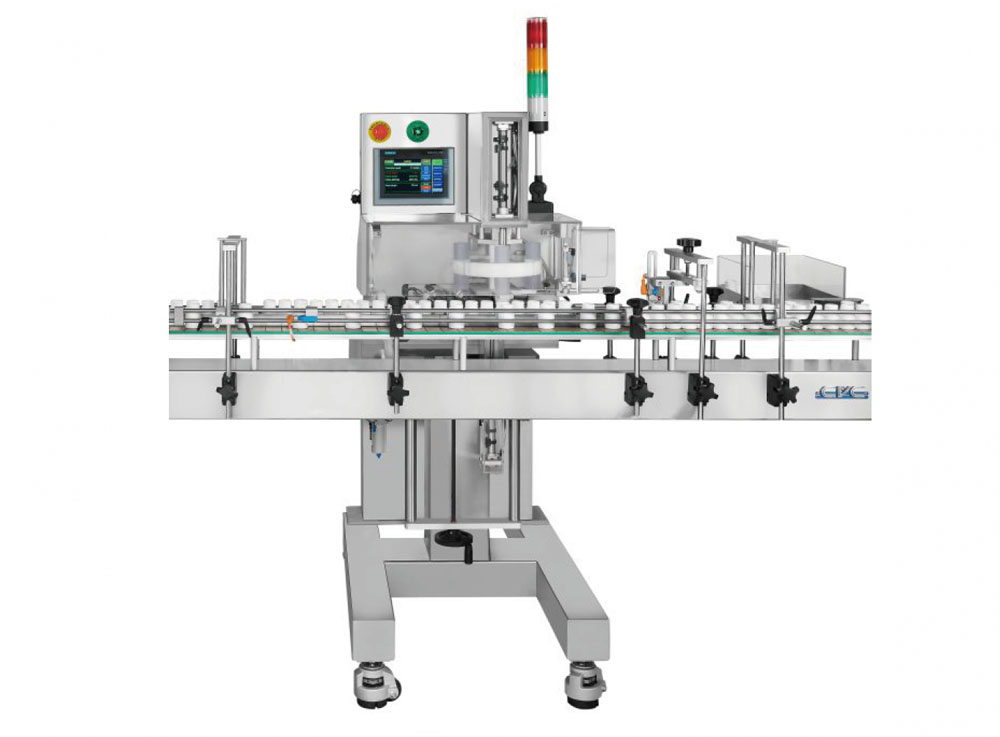

Chuck Capper CVC 3034-2

The compact-designed Chuck Capper CVC 3034-2 Chuck Capping System provides excellent capping performance with maximum output of 60 BPM(bottles per min.).

Beschrijving

Chuck Capper

The compact-designed Chuck Capper CVC 3034-2 Chuck Capping System provides excellent capping performance with maximum output of 60 BPM(bottles per min.). The machine is great to integrate with a variety of bottle packaging lines.

CVC Servo Chuck Capping System is available for the following types of capping applications:

- Plastic Screw-on caps

- Snap-on caps

- Aluminum ROPP caps

- Push-in stoppers, and plugs

- Pumps and triggers

STANDARD FEATURES Chuck Capper

- Production Output is up to 60 bottles per min. (Actual output will be depending on customer’s and caps. Our factory evaluation is required.)

- 2 Servo Driven Capping Heads.

- Table top design features ease of machine cleanup and operator’s access.

- Stainless steel construction, meeting GMP regulations.

- Servo motor driven system is applied for consistent torque application.

- Siemens PLC and 7” Touch Screen Panel HMI.

- Up to 50 Recipes which allow operator to perform quick storage and recall of counting job memory.

- Main Drive System is servo motor driven.

- Capping head up/down and rotation are driven by advanced servo motors, which feature precise capping control.

- Capping torque inspection system.

- CE standard PC safety guard.

- Type 304 stainless steel bin, frame, enclosure panels.

- ISO 9001 : 2015 certified.

AVAILABLE OPTIONS Chuck Capper

- 21CFR Part 11 compliance

- OPC UA for data collection

- Cap Prefeeder (Cap Stock Elevator/Hopper)

- Fallen bottle detection

- Bottle & cap detection system is used for foil liner and crooked caps detection.

- Rejection system is in conjunction with verification devices to removing unqualified containers: cocked caps, missing foil liners, low capping torque level (if capping torque is lower than set torque)

- Rejection verification check

- Bottle format changeover parts

- Cap format changeover parts

- Type 316L stainless steel contact parts.

| CVC 3034-2 Technical Specifications | |

| Max. Productivity | Up to 60 Bottles per Minute(BPM) based on 100ml |

| (subject to trial confirmation) | round bottle |

| Applicable Bottle | Cap: CRC, CT For press-on caps, please consult with CVC Engineering team Bottle: Plastic bottle, Glass bottle For irregular shaped bottles, please consult with CVC Engineering team. |

| Applicable Size | Bottle Dia.: Ø30 mm – Ø110 mm Bottle Height: 50 mm – 220 mm Cap Dia.: Ø30 mm – Ø60 mm Cap Height: 8 mm – 22 mm |

| Power Supply | 380 V/ 60 HZ/ 3 PH |

| Power Consumption | 9,000 VA (About 25 A) |

| Air Pressure | 6 bar / Minimum 87 psi |

| Air Consumption | 800 NLit/min (28 CFM) |

| Consumption Machine Dimensions | L.3700 (Including conveyor) x W.2753 (Including vibrator) x H.2200 (mm) (Including tower lamp) L.1515 x W.1465 x H.1900 (mm) (Does not include conveyor) |

| Net Weight | 1150 Kg (Not including vibrator) |

CVC Technologies

CVC Technologies was founded in 1979, CVC has been committed to a professional manufacturer of pharmaceutical packaging equipment. Such as capsules and tablets counting machine, liquid filling machine, powder filling machine, bottle unscrambler, air washing machine, labeling machine, cotton inserter, desiccant inserter, aluminum foil sealing machine, etc.,

CVC provides pharmaceutical, biotechnology, nutraceutical and other packaging machinery and equipment and production packaging lines. And so on, we are constantly improving in technology, which is comparable to European and American grade specifications and sold to all parts of the world. The quality of the equipment is strictly controlled. All pharmaceutical packaging machinery and equipment have obtained international certification standards, such as ISO 9001, CE, FDA, cG.M.P., PIC / S GMP.